Why Industrial Bulk Plastic Containers Are Vital for Large-Scale Logistics

Wiki Article

Comprehending the Benefits of Mass Containers in Enhancing Item Handling and Circulation Processes

Mass containers play an important function in enhancing product handling and distribution. Their style promotes reliable supply administration and lessens waste, resulting in cost savings. In addition, these containers improve transport effectiveness and improve product security throughout transportation. As markets remain to look for lasting remedies, the versatility of bulk containers comes to be significantly pertinent. Discovering their numerous benefits discloses insights that can transform functional approaches throughout supply chains. What might these understandings involve for future practices?The Duty of Mass Containers in Stock Management

Bulk containers play a crucial duty in inventory management by improving the storage and transportation of big quantities of goods. These containers help with efficient company and easy access to products, thereby reducing the moment invested finding products within storehouses. Their standardized sizes and designs permit for optimum use of space, optimizing storage capabilities. Additionally, mass containers improve the accuracy of supply tracking, as they can be easily identified and scanned for supply monitoring systems. The robust nature of these containers secures goods from damages during handling and transportation, ensuring product stability. Generally, mass containers contribute substantially to a much more arranged, effective, and trustworthy supply management procedure, sustaining organizations in meeting need and maintaining operational performance.Cost-Effectiveness of Mass Containers

The cost-effectiveness of bulk containers plays a substantial duty in modern product handling. By reducing product packaging expenditures and enhancing transport logistics, services can accomplish considerable financial savings. This financial efficiency not only boosts success yet additionally adds to structured procedures.Minimized Product Packaging Prices

Lots of services find that using mass containers notably minimizes product packaging prices. By combining items into larger containers, business can substantially lower the quantity of product packaging product required. This reduction not just lowers the costs related to buying product packaging products yet likewise lessens waste disposal expenditures. In addition, mass containers simplify the packaging process, enabling faster and a lot more effective packing operations. Because of this, labor expenses associated with managing smaller bundles are also decreased. The longevity of mass containers typically leads to fewer item damages throughout transportation, thus decreasing the demand for replacement packaging. On the whole, the fostering of bulk containers stands for a tactical approach to reducing product packaging expenditures while improving operational effectivenessEfficient Transport Savings

Substantial cost savings in transport expenses can be achieved via the usage of bulk containers. By making the most of lots capacities, bulk containers minimize the number of journeys called for to move goods, causing lower fuel costs and lowered labor expenses. Their standard measurements facilitate effective stacking and filling, optimizing area within transport automobiles. Furthermore, mass containers frequently consider much less than conventional product packaging, permitting increased payloads without going beyond weight limits, additionally boosting cost efficiency. The longevity of these containers minimizes product damage during transit, reducing returns and losses. Overall, the integration of bulk containers in logistics not only enhances transport procedures yet also considerably adds to cost-effectiveness, making them a vital component in modern-day supply chain management.Reducing Waste With Bulk Containers

Mass containers play a crucial role in lessening waste within product handling systems. By reducing material waste and promoting efficient resource usage, these containers contribute substantially to sustainability efforts. This change in the direction of lasting packaging services not only benefits the atmosphere yet additionally improves functional performance.Minimizing Product Waste

Reliable monitoring of product waste is an essential problem in product handling, and utilizing bulk containers can play a critical function in addressing this issue. By increasing the volume of materials delivered at one time, bulk containers significantly decrease the variety of deliveries required, therefore decreasing excess packaging waste. Their robust layout likewise avoids splilling and damages during transportation, further limiting product loss - Industrial Bulk Plastic Containers. In addition, bulk containers are commonly recyclable, promoting a circular economy that motivates sustainability. The standardization of these containers simplifies inventory management and decreases the threat of over-ordering, which can result in waste. As companies venture for efficiency, taking on bulk containers becomes a reliable strategy for lowering material waste in different distribution proceduresEfficient Source Application

While intending for perfect performance, numerous organizations find that the usage of bulk containers significantly improves source monitoring. These containers help with structured procedures by minimizing the regularity of dealing with and transportation, which consequently lessens the chance of product loss and damages. By settling materials into larger devices, business can maximize storage space and minimize the need for too much product packaging. This method not just decreases material costs however additionally reduces labor connected with managing smaller sized packages. Furthermore, mass containers commonly have a longer life-span compared to traditional packaging, causing reduced substitute prices and lowered waste. Ultimately, the adoption of bulk containers promotes a much more reliable use sources, adding to improved operational performance and price savings in the supply chain.

Sustainable Packaging Solutions

A significant benefit of making use of bulk containers depends on their prospective to reduce waste in product packaging processes. These containers are made for reuse, noticeably decreasing the requirement for single-use packaging materials, which contribute to environmental degradation. By settling product storage space and transport, mass containers enhance space and decrease the overall quantity of products needed, thus lowering the carbon impact linked with production and throwing away standard packaging. Furthermore, their sturdiness guarantees that they can endure multiple journeys, advertising a circular economy. As organizations significantly adopt lasting methods, the integration of mass containers into supply chains stands for a positive approach to lowering waste and improving efficiency, inevitably sustaining broader environmental goals and business social obligation initiatives.Enhancing Transport Efficiency

Optimizing transport effectiveness is essential for services utilizing bulk containers in product handling. Mass containers are developed to make the most of room utilization during transportation, permitting larger amounts of items to be shipped all at once. This reduction in trips Shop Bulk Plastic Containers translates to lower transportation prices and decreased carbon discharges, adding to more sustainable logistics methods. In addition, the harmony of bulk containers simplifies loading and discharging procedures, decreasing dealing with time and labor prices. Their sturdy building additionally supplies protection against damage, decreasing losses throughout transportation. As an outcome, companies can attain quicker turnaround times, boosting total supply chain effectiveness. By applying mass containers, businesses can greatly improve their transportation logistics, eventually bring about raised profitability and an one-upmanship in the marketplace.

Improving Product Safety and Quality

Guaranteeing item safety and security and quality is critical for companies that use mass containers in item handling, as these containers are specifically designed to secure contents during storage space and transportation. The durable building and construction of bulk containers safeguards products from environmental elements such as moisture, dust, and contamination, which can jeopardize stability. Furthermore, their closed seals decrease exposure to air, therefore maintaining freshness and stopping perishing. Furthermore, bulk containers promote conformity with security regulations by giving clear labeling and traceability, which are crucial in numerous industries, consisting of food and drugs. By utilizing bulk containers, business can effectively lower the risk of damages during transportation and handling, making certain that products reach their location in prime condition, consequently enhancing client complete satisfaction and trust fund.Flexibility and Flexibility of Bulk Containers

Mass containers offer remarkable adaptability and flexibility, making them suitable for a large range of sectors and applications. Their design enables the efficient handling of different products, including powders, fluids, and granules, catering to markets such as food, drugs, and chemicals. These containers can be easily customized or customized to satisfy specific operational demands, helping with smooth assimilation into existing supply chains. Additionally, their stackable nature enhances storage area, boosting stockroom efficiency. The ability to stand up to various ecological problems better expands their usability across diverse settings, from manufacturing to transportation. This flexibility not just streamlines logistics but additionally sustains services in meeting changing needs, emphasizing the importance of mass containers in contemporary item dealing with systems.Sustainability Advantages of Using Mass Containers

The adaptability of bulk containers not just improves functional performance however likewise adds substantially to sustainability efforts across various sectors. By lowering the need for single-use product packaging, bulk containers reduce waste generation, leading to a reduced ecological footprint. Their reusable nature allows firms to substantially reduce material consumption, while their style promotes reliable transport, reducing gas usage and greenhouse gas discharges. Additionally, bulk containers can be quickly cleansed and repurposed, even more extending their lifecycle and lessening the demand for new production sources. This sustainable strategy lines up with growing customer preferences for eco-friendly practices, enabling businesses to boost their brand photo while supporting ecological stewardship. In general, the execution of bulk containers cultivates a much more lasting design for item handling and distribution.

Regularly Asked Inquiries

What Products Are Bulk Containers Usually Made From?

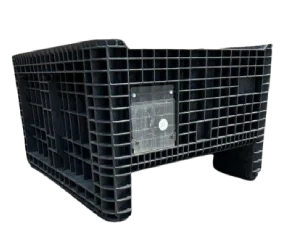

Bulk containers are typically made from products such as plastic, metal, timber, or composite products. These choices depend upon the container's intended usage, longevity demands, and the kinds of items being kept or transferred.

Exactly How Do Bulk Containers Adhere To Industry Regulations?

Mass containers adhere to sector laws by sticking to security standards, using accepted products, and ensuring proper labeling. Regular inspections and certifications further guarantee they meet health, environmental, and transport guidelines, protecting product honesty throughout the supply chain.Can Mass Containers Be Customized for Specific Products?

Yes, bulk containers can be tailored for details products. Makers commonly design them to meet unique requirements, making certain compatibility with numerous products, boosting security, and optimizing efficiency during handling and circulation customized to details market requirements.What Is the Average Life-span of a Bulk Container?

The average life-span of a mass container usually varies from 5 to two decades, relying on the products utilized, frequency of usage, and maintenance practices. Proper treatment can considerably extend its use and performance.

Exactly how Do I Tidy and Maintain Bulk Containers Properly?

The durability of mass containers commonly leads to less product problems during transportation, consequently decreasing the demand for replacement product packaging. Reliable administration of material waste is a critical worry in product handling, and utilizing bulk containers can play an essential function in resolving this issue. By combining item storage and transportation, mass containers maximize space and reduce the overall volume of products called for, thus reducing the carbon impact associated with manufacturing and disposing of standard packaging. Enhancing transport efficiency is essential for services making use of bulk containers in product handling. Making certain product security and high quality is extremely important for organizations that utilize mass containers in item handling, as these containers are especially made to protect components throughout storage space and transport.

Report this wiki page